General Product Questions

Ordering Questions

- How do I order it?

- Where is my order?

- How long does it take?

- Can I get matching straight moulding?

- Do I need a template?

- How do I pay for it?

- What do you have "in-stock"?

- If I don't see what I need, can you make it for me?

- How does it ship?

- Item X and item Y look the same. What am I missing?

- How can I tell if your flexible moulding matches my wood?

- Do you offer wood moulding?

- How much is shipping?

Questions about the Company

How flexible is it? Can I bend it on the job?

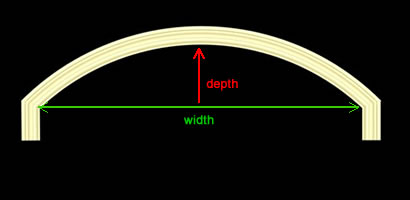

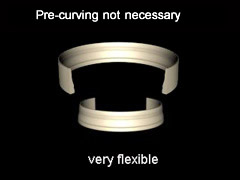

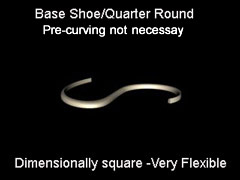

Flexibility depends upon the size of the moulding and the direction it is being bent. Moulding that is bent in the direction of the lesser dimension (such as base moulding on a curved wall) or small dimensionally square moulding (such as quarter round and base shoe) are very flexible. These can be ordered straight and bent on the job.

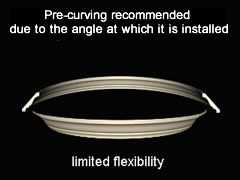

Moulding that is bending in the direction of the larger dimension (IE casing on an arch top window and crown) usually requires pre-curving to the approximate radius of the arch for the best possible fit and finish. Even though pre-curved, the material remains flexible and will "flex to fit" minor variations.

Pre-curving to a specified radius does not add any additional cost or time to the order.

The minimum radius attainable depends upon the thickness of the moulding and the direction that it is bending. The minimum recommended radius for a 3/4" thick moulding (when bending in the direction of the 3/4" dimension) is 4 inches. Flexible trim should not be used on bullnosed corners with a radius of less than 4 inches.

It is possible to machine shape flexible moldings. When machining flexible molding, the material must be securely held to the fence, guide or holder especially at the beginning of the cut, when the material first enters the machine cutter. Always make several small incremental cuts rather than one large one.

Machining of stain grade material will remove the grain texture from the cut surface.

YES! Flexible mouldings are not affected by salt, moisture, heat or extreme cold. Many builders and homeowners have selected to replace even straight exterior moldings with flexible mouldings because of their durability in even the harshest environments.

Flex Trim®

Flex Trim is a unique polyurethane blend developed by Flex Trim Industries specifically for the manufacture of flexible moldings for the construction trade. It is unlike any other product in composition and should not be confused with other less expensive "knock offs". Our most recent improvements to Flex Trim make it stronger, more durable and greatly improve its stain ability.

Can I get matching straight moulding?

Due to the cost of shipping lengths of straight moulding, we do not offer matching straight wood moulding. However with over 50,000 styles of moulding available, we are certain to have a match to a locally available wood moulding that will meet your needs.

Contrary to popular belief, flexible moulding is not an extrusion process done with machines. Flexible moulding is a labor intensive, "hand made" process requiring time and attention to detail. Although some items are made and stocked, most orders ship in 12-14 days plus time in transit.

In-Stock items usually in 2 to 3 business days. Items with "In-Stock" lengths will be marked as such.

IN STOCK ITEMS ARE STANDARD FLEX TRIM MATERIAL. IF ZzzFLEX IS DESIRED PLEASE CHOOSE THE CUSTOM ORDER FORM.

Most orders do not require templates. Templates are only required for irregular curves such as elliptical arches, ovals and compound curves. Templates are NOT required for "eyebrow" arches. See "Template Instructions" for more information.